- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

-

Your selected country is

United States

- Change country/language

-

Promotions

-

sk-testpage

-

BD Primer Program

-

BD Discovery 2021

-

Reagents

-

DO NOT PUBLISH

-

Reagentes Com Valor Promocional

-

Lunch Box Giveaway

-

EQCプログラム 外部精度管理 施設間精度管理

-

Backbone Reagents Promo

-

Backbone Reagents Promo

-

Classic Dyes

-

Back to Lab

-

End of Year

-

Tcell Backbone Panel Promotion

-

BD Horizon™ Human T Cell Backbone Panel

-

New Lab Promotion

-

Flash Sale

-

BD Panel Design Program

-

Real Dyes Sample Offer

-

BD’s 50 Years of Innovation Research Instrument Promotion

-

BD FACSLyric™ Flow Cytometers 50th Anniversary Promo

-

BD FACSAria™ Customer Loyalty Promotion

-

FlowJo™ Software Promotion

-

BD® Research Cloud Promotion

-

sk-testpage

-

Custom BD® AbSeq

-

Custom AbSeq FAQ Answer 2

-

Custom AbSeq FAQ Answer 3

-

Custom AbSeq FAQ Answer 4

-

Custom AbSeq FAQ Answer 5

-

Custom AbSeq FAQ Answer 6

-

Custom AbSeq FAQ Answer 7

-

Custom AbSeq FAQ Answer 8

-

Custom AbSeq FAQ Answer 9

-

Custom AbSeq FAQ Answer 10

-

Custom AbSeq FAQ Answer 11

-

Custom AbSeq FAQ Answer 12

-

Custom AbSeq FAQ Answer 13

-

Custom AbSeq FAQ Answer 14

-

Custom AbSeq FAQ Answer 15

-

Custom AbSeq FAQ Answer 16

-

Custom AbSeq FAQ Answer 17

-

Custom AbSeq FAQ Answer 18

-

Custom AbSeq FAQ Answer 19

-

Custom AbSeq FAQ Answer 20

-

Custom AbSeq FAQ Answer 2

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

- United States (English)

-

Change country/language

Old Browser

Your account has been put on hold due to inactivity. To re-activate, check your account information and make all necessary updates.

Looks like you're visiting us from {{countryName}}.

Would you like to remain on the current country site or be redirected to one based on your location?

live copy GB

Your account has been put on hold due to inactivity. To re-activate, check your account information and make all necessary updates.

Section Title

Title

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Please select your operating system

Testing Sub Tab Content Title

Testing Sub Tab Content Title

Test Tab Title

Testing Sub Tab Content Description Testing Sub Tab Content Description Testing Sub Tab Content Description Testing Sub Tab Content Description Testing Sub Tab Content DescriptionTesting Sub Tab Content Description v Testing Sub Tab Content Description v Testing Sub Tab Content Description Testing Sub Tab Content Description v Testing Sub Tab Content Descriptionv Testing Sub Tab Content Description

Testing Sub Tab Content Description Testing Sub Tab Content Descriptionv Testing Sub Tab Content Description Testing Sub Tab Content Description Testing Sub Tab Content Description Testing Sub Tab Content Description v v

Testing Sub Tab Content Title

Testing Sub Tab Content Title

Test Tab Title

Testing Sub Tab Content Description Testing Sub Tab Content Description Testing Sub Tab Content Description Testing Sub Tab Content Description Testing Sub Tab Content DescriptionTesting Sub Tab Content Description v Testing Sub Tab Content Description v Testing Sub Tab Content Description Testing Sub Tab Content Description v Testing Sub Tab Content Descriptionv Testing Sub Tab Content Description

Testing Sub Tab Content Description Testing Sub Tab Content Descriptionv Testing Sub Tab Content Description Testing Sub Tab Content Description Testing Sub Tab Content Description Testing Sub Tab Content Description v v

Language Master

Language Master

Do Not Publish

This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master.

This is the author page that need to be done on the language master. This is the author page that need to be done on the language master.

Automated sample preparation and antibody cocktail preparation to improve efficiency

Flow cytometry sample preparation can be automated using the BD FACSLyric™ Flow Cytometer integrated with the BD FACSDuet™ Premium Sample Preparation System. The sample preparation system is designed to complement and physically integrate with the flow cytometer to provide a complete end-to-end walkaway solution. This system helps streamline workflow and drive productivity while allowing for on-board automated antibody cocktail preparation which eliminates risk of errors due to manual pipetting. It supports different types of blood collection tubes and a wide variety of reagent vials delivering flexibility. The BD FACSLyric™ Flow Cytometer enables efficiency and productivity with automated laser alignment and compensation stability over 60 days and allows flexibility for acquisition using a universal loader with 21 different loading options including multiwell plates. The distinctive assay portability feature allows easy and efficient transferability of assays across sites.

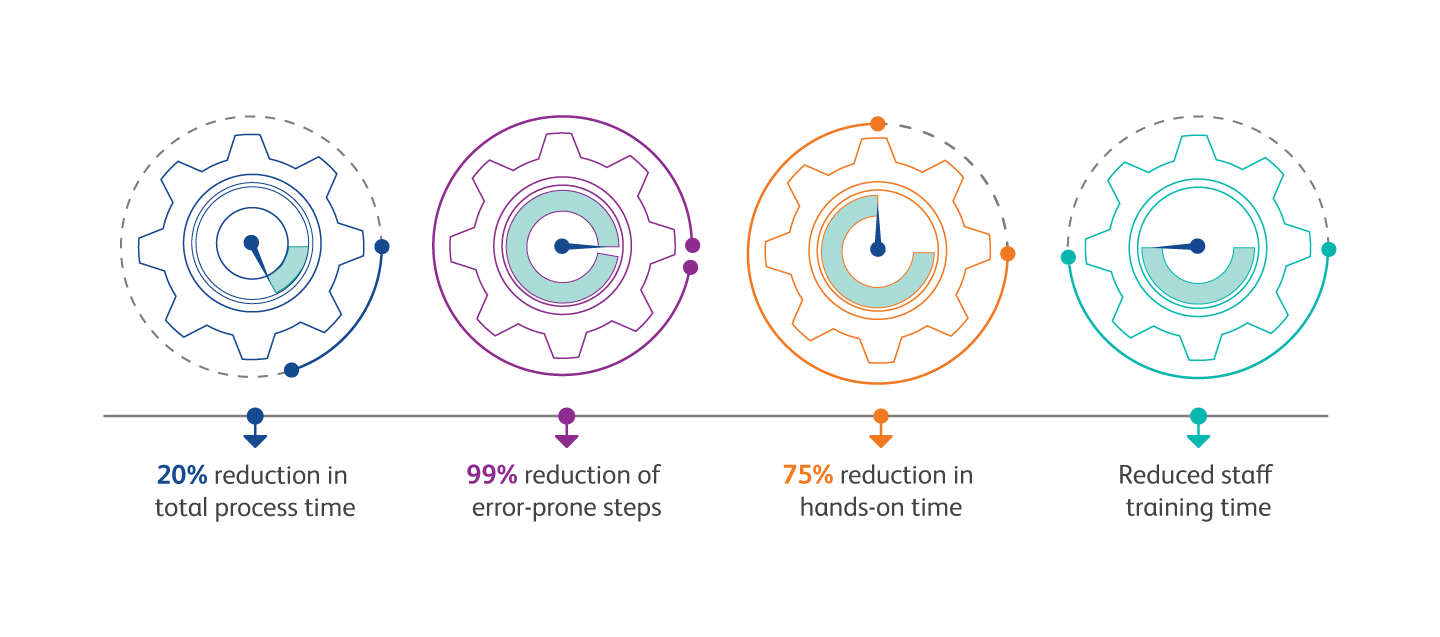

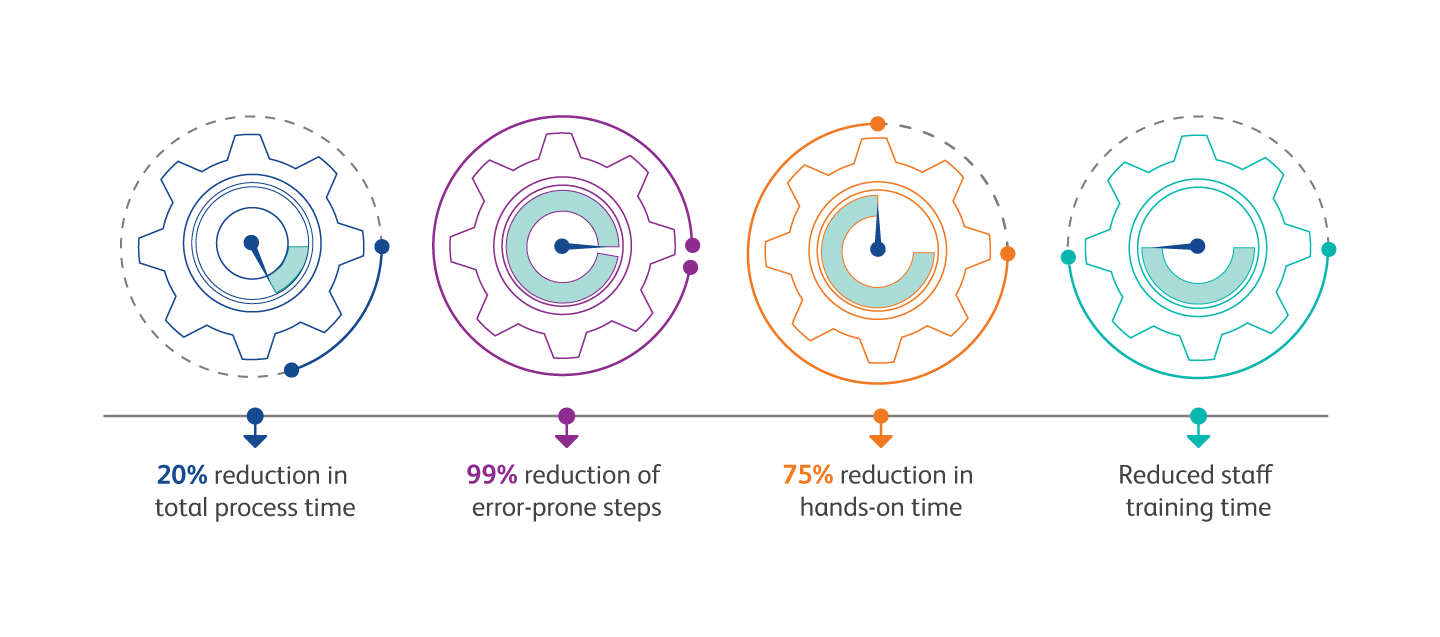

A study demonstrated that samples prepared with 20x BD Multitest™ 6-color TBNK Reagent + BD Trucount™ Tubes on the automated BD FACSDuet™ System Integrated with BD FACSLyric™ Flow Cytometer vs. manual preparation led to:

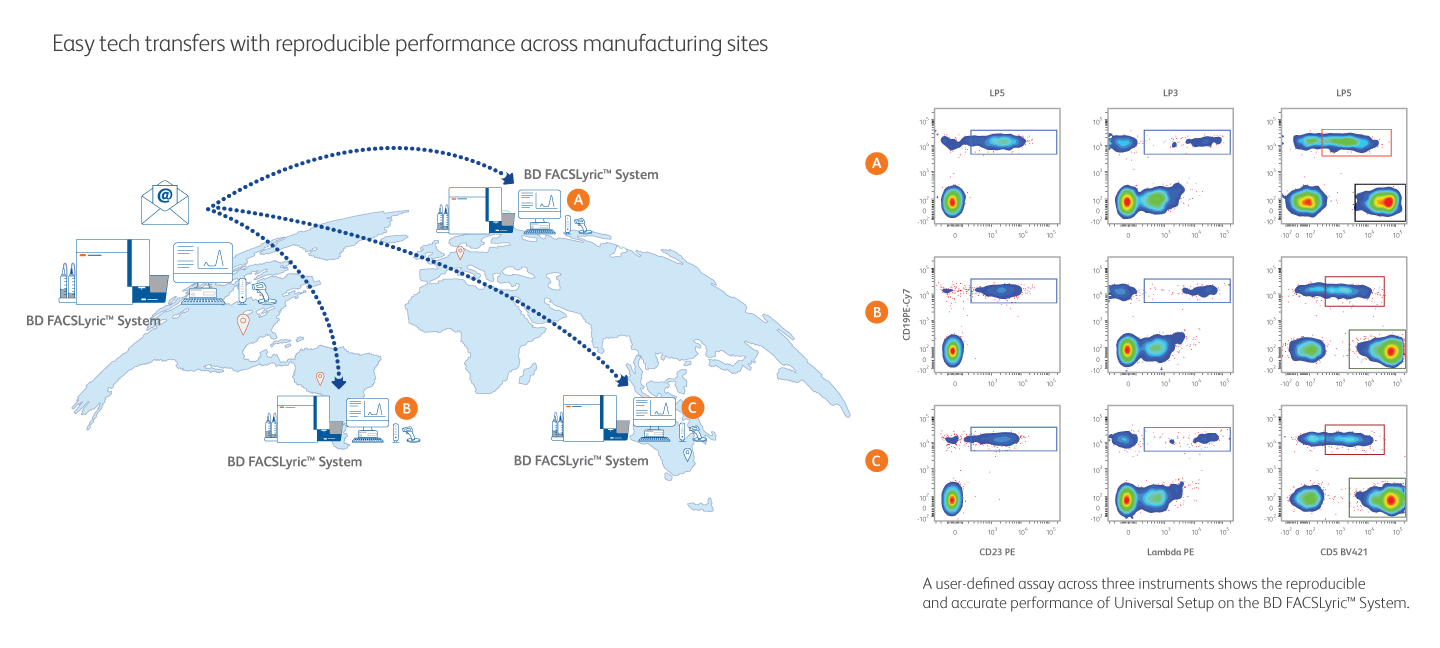

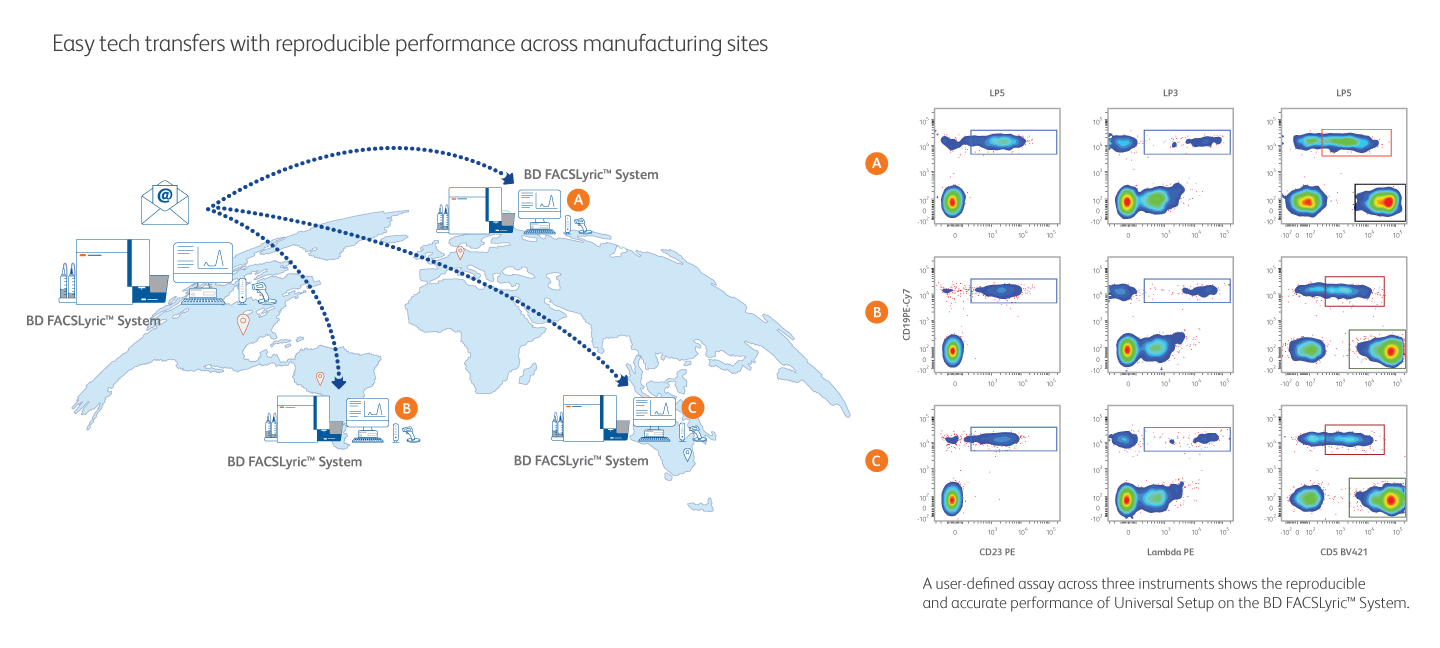

Consistent reagent and instrument performance enables global collaboration

The BD FACSLyric™ Flow Cytometer has a unique assay portability feature that allows transfer of user-defined assays from one instrument to another, providing standardization and reproducible results across global manufacturing sites. This high-performance, highly sensitive flow cytometer demonstrates exceptional resolution and improved separation to make dim and rare populations easier to resolve. The BD FACSDuet™ Premium Sample Preparation System provides accuracy and consistency in operation by minimizing manual intervention and an intuitive software interface minimizing training and variations due to different operators’ experience.

Contract manufacturing of ready-to-use multicolor reagents panels in liquid, dried, or lyophilized formats are customized to your specifications and requirements. Dried and lyophilized reagents are manufactured using proprietary BD Horizon™ Chroma Dried Panel technology, and have extended stability compared to liquid reagents. All-in-one tube format reduces the need for manual pipetting and cocktailing which improves consistency, reduces operator errors and day-to-day variability and saves time. Certain preformulated dried reagent cocktails are available, like BD Horizon™ Dri TBNK + CD20 Panel for cell therapy research workflows.

Functions in BD FACSuite™ Application assist in supporting 21 CFR Part 11 compliance and electronic record integrity

Our flagship analyzer, BD FACSLyric™ Flow Cytometer is upgradeable to a 12-color configuration. It is powered by the BD FACSuite™ Application used for acquisition and analysis that helps to support 21 CFR Part 11 compliance with password protection, electronic signatures, automatic record keeping and audit trails. We provide operational qualification (OQ) by a BD field service engineer for features related to 21 CFR Part 11 compliance for the BD FACSLyric™ Flow Cytometer and the BD FACSuite™ Application. The BD FACSDuet™ Premium Sample Preparation System allows traceability of samples and worklists through carrier barcoding and supports ISO 15189-accredited labs with compliance with complete workflow traceability.

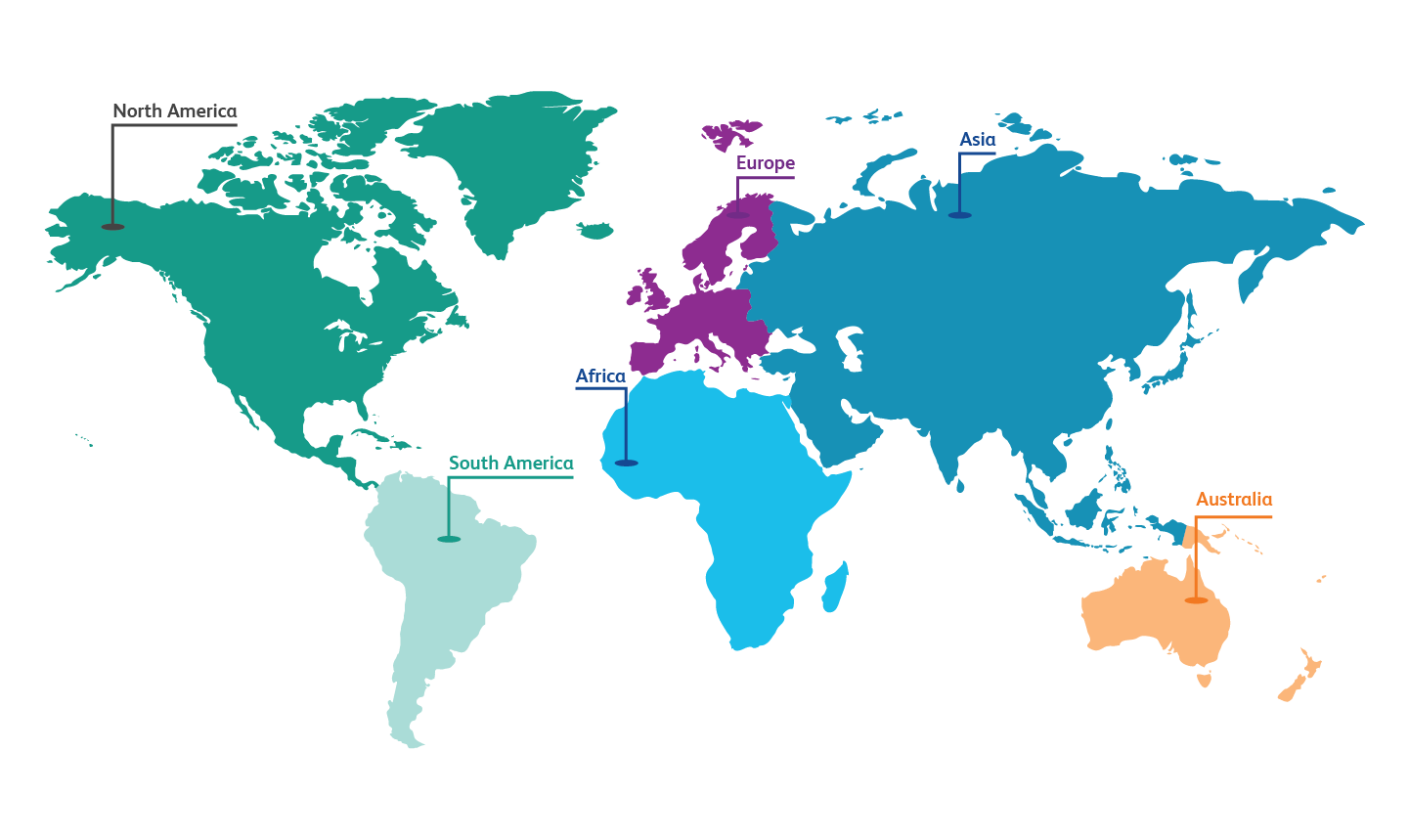

Global install base with guaranteed technical service support

With you in the driver’s seat and BD as your single partner for flow cytometry reagents, instruments and services you will benefits from synergies in user workflows and support provided. BD Technical Services offer installation qualification (IQ), operational qualification (OQ) and technical service support to minimize instrument downtime. BD offers qualification assistance to help customers meet current Good Manufacturing Practice (cGMP) and Good Laboratory Practice (cGLP) standards. Explore our contract manufacturing offering of multicolor panels in liquid, dried or lyophilized formats to minimize errors and time associated with manual cocktailing of reagents. The BD FACSLyric™ Flow Cytometer has an install base of more than 3,000 units globally.

Language Master

Language Master

Do Not Publish

This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master. This is the author page that need to be done on the language master.

This is the author page that need to be done on the language master. This is the author page that need to be done on the language master.

Automated sample preparation and antibody cocktail preparation to improve efficiency

Flow cytometry sample preparation can be automated using the BD FACSLyric™ Flow Cytometer integrated with the BD FACSDuet™ Premium Sample Preparation System. The sample preparation system is designed to complement and physically integrate with the flow cytometer to provide a complete end-to-end walkaway solution. This system helps streamline workflow and drive productivity while allowing for on-board automated antibody cocktail preparation which eliminates risk of errors due to manual pipetting. It supports different types of blood collection tubes and a wide variety of reagent vials delivering flexibility. The BD FACSLyric™ Flow Cytometer enables efficiency and productivity with automated laser alignment and compensation stability over 60 days and allows flexibility for acquisition using a universal loader with 21 different loading options including multiwell plates. The distinctive assay portability feature allows easy and efficient transferability of assays across sites.

A study demonstrated that samples prepared with 20x BD Multitest™ 6-color TBNK Reagent + BD Trucount™ Tubes on the automated BD FACSDuet™ System Integrated with BD FACSLyric™ Flow Cytometer vs. manual preparation led to:

Consistent reagent and instrument performance enables global collaboration

The BD FACSLyric™ Flow Cytometer has a unique assay portability feature that allows transfer of user-defined assays from one instrument to another, providing standardization and reproducible results across global manufacturing sites. This high-performance, highly sensitive flow cytometer demonstrates exceptional resolution and improved separation to make dim and rare populations easier to resolve. The BD FACSDuet™ Premium Sample Preparation System provides accuracy and consistency in operation by minimizing manual intervention and an intuitive software interface minimizing training and variations due to different operators’ experience.

Contract manufacturing of ready-to-use multicolor reagents panels in liquid, dried, or lyophilized formats are customized to your specifications and requirements. Dried and lyophilized reagents are manufactured using proprietary BD Horizon™ Chroma Dried Panel technology, and have extended stability compared to liquid reagents. All-in-one tube format reduces the need for manual pipetting and cocktailing which improves consistency, reduces operator errors and day-to-day variability and saves time. Certain preformulated dried reagent cocktails are available, like BD Horizon™ Dri TBNK + CD20 Panel for cell therapy research workflows.

Functions in BD FACSuite™ Application assist in supporting 21 CFR Part 11 compliance and electronic record integrity

Our flagship analyzer, BD FACSLyric™ Flow Cytometer is upgradeable to a 12-color configuration. It is powered by the BD FACSuite™ Application used for acquisition and analysis that helps to support 21 CFR Part 11 compliance with password protection, electronic signatures, automatic record keeping and audit trails. We provide operational qualification (OQ) by a BD field service engineer for features related to 21 CFR Part 11 compliance for the BD FACSLyric™ Flow Cytometer and the BD FACSuite™ Application. The BD FACSDuet™ Premium Sample Preparation System allows traceability of samples and worklists through carrier barcoding and supports ISO 15189-accredited labs with compliance with complete workflow traceability.

Global install base with guaranteed technical service support

With you in the driver’s seat and BD as your single partner for flow cytometry reagents, instruments and services you will benefits from synergies in user workflows and support provided. BD Technical Services offer installation qualification (IQ), operational qualification (OQ) and technical service support to minimize instrument downtime. BD offers qualification assistance to help customers meet current Good Manufacturing Practice (cGMP) and Good Laboratory Practice (cGLP) standards. Explore our contract manufacturing offering of multicolor panels in liquid, dried or lyophilized formats to minimize errors and time associated with manual cocktailing of reagents. The BD FACSLyric™ Flow Cytometer has an install base of more than 3,000 units globally.

Report a Site Issue

This form is intended to help us improve our website experience. For other support, please visit our Contact Us page.